Product Filter

Disco-DFD6361

Availability: Product not in stock!

Φ300 mm Facing dual spindle DBG

Enhanced dicing throughput

The DFD6361 enhances throughput in two distinct ways. DISCO’s facing dual design and a reduction in the distance between the blades help to control total cut time, while high-magnification microscopes (standard) and non-contact setup sensors (option) for both Z1 and Z2 reduce the time required for non-dicing sequences, such as kerf check and blade setup.

Consistent cut quality

DFD6361 offers highly consistent and dependable cut quality through the new Synchro Spindle™ featuring superior radial rigidity. An atomizing nozzle cleaning mechanism can also be installed in the spinner unit as an option to effectively clean wafers after dicing (Patent no.3410385).

Improved usability

Auto-open/close wheel cover and spindle shaft-lock feature make blade replacement quick and easy. In addition, the condition monitor relays processing status and key equipment information in real time. DFD6361 also has a cutting water flow rate control feature, making it possible to manage the flow rate on the screen. An adjustable LCD touch screen with GUI (Graphical User Interface) has also been adopted.

Small footprint

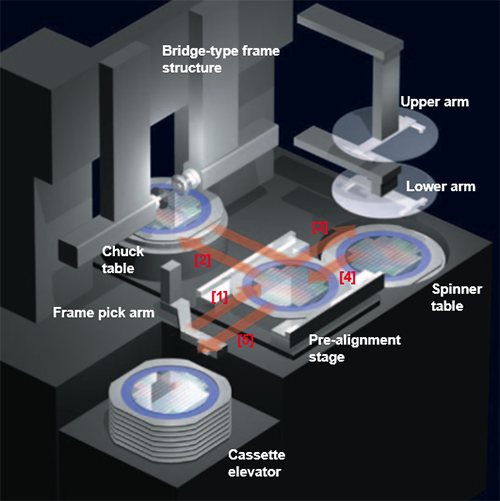

The bridge-type frame structure and improved wafer handling system contribute to the compact size and small footprint of the DFD6361.

Spindle lineup

The 1.2 kW spindle (standard) features superior rigidity. A center thrust design gives the 1.8 kW spindle (option, uses 2 ” blades) and the 2.2 kW spindle (option, uses 3 ” blades) extra rigidity for processing glass, ceramics, and other high processing load materials.

DFD6340 Operation flow

- Frame pick arm moves the workpiece from the cassette to the pre-alignment stage →

-

After centering on the pre-alignment stage, the lower arm moves the workpiece to the chuck table → cutting →

-

Upper arm moves the workpiece to the spinner table → cleaning and drying →

- Lower arm moves the workpiece to the pre-alignment stage →

- Frame pick arm returns the workpiece to the cassette

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.