Product Filter

DFD6760

Availability: Product not in stock!

Φ300 mm

Facing dual spindle

Fully automatic dicing saw with dual chuck tables

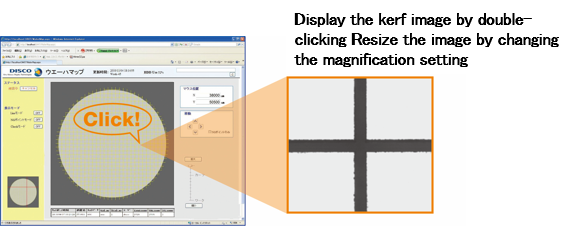

DFD6760 is a high end model which has further enhanced productivity from the existing model, DFD6362. Since this dicing saw has two chuck tables (hereafter called C/T), it is possible for transfer and alignment to occur on one chuck table, while processing is performed on the other chuck table. This shortens the spindle waiting time for processing considerably and improves productivity. In addition, inspection and measurement operations including processed workpiece image recording and workpiece thickness measurement using an NSD* can be performed on one chuck table, while processing proceeds on the other chuck table to maintain throughput. Increased X, Y and Z-axis feed speeds (same as the existing model) also contribute to the reduced processing time.

* Non-contact Surface Detector (option)

Enhancing the quality of thin wafer processing while maintaining throughput

For thin wafer step cuts, controlling the cut depth from the wafer surface is important. The NSD that is used to control the cut depth makes it possible to measure the wafer upper surface height very accurately. Typically, the NSD requires about 10 seconds to make the measurements, but in the case of the DFD6760, the NSD makes the measurements while processing the wafer on the other chuck table, so the throughput does not deteriorate.

Meeting the need for traceability

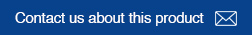

Since the DFD6760 is equipped with two chuck tables, while dicing is performed on one chuck table, kerf images of the workpiece after processing can be saved and processing quality can be recorded using the other chuck table. In recent years at production facilities, there has been a demand for traceability. If a defect is found in a device, the DFD6760 can provide the records to check or certify product quality.

Various measures to prevent particles

The cut section atomizing nozzle, wheel cover, and chuck table water curtain, which have been well received in the DFD6362, are selectable as optional accessories in accordance with workpiece characteristics.

Easy operation

The GUI (Graphical User Interface) implemented on the DFD6362, which has been recognized for its ease of use, has been included on the DFD6760. This is combined with an LCD touch panel for stress-free operation.

Dicer image viewer and software for browsing processing records

Process flow comparison with existing model

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.