Product Filter

VT07/12 Series

Availability: Product not in stock!

Vitrified bond blade for high-load processing

The VT07/12 series can handle various materials from processing of difficult-to-cut workpieces to

edge trimming of silicon wafers

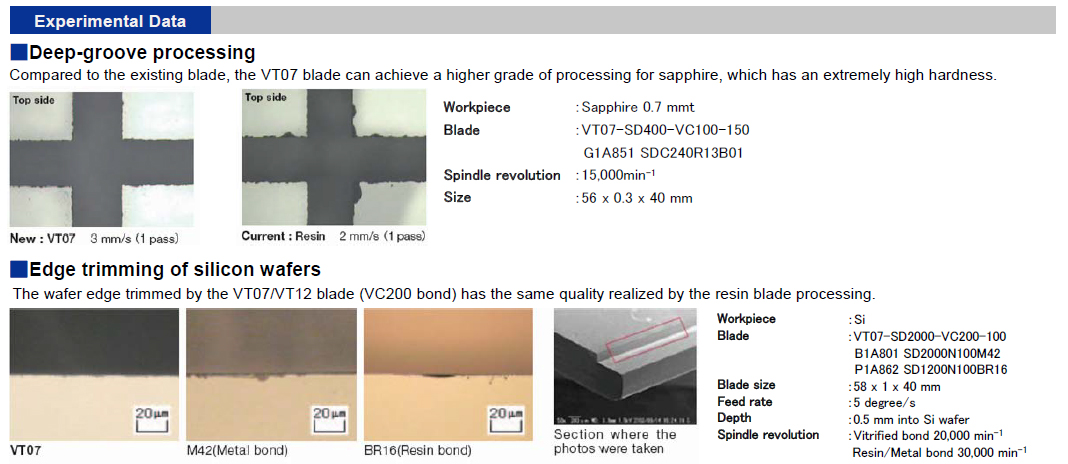

This bond series employs a vitrified bond that has been difficult to manufacture into thin blades so far. These blades can process with an acute degree of straightness and dimensional accuracy for high-load processing by using the excellent rigidity and cutting ability of the vitrified bond. As a result, VT07/12 realizes quality processing for difficult-to-cut materials such as silicon nitride. Thanks to the enhanced bond line-up, this bond series also realizes processing in various fields, such as edge trimming of silicon wafers.

The VT07/12 series can handle various materials from processing of difficult-to-cut workpieces to

edge trimming of silicon wafers

This bond series employs a vitrified bond that has been difficult to manufacture into thin blades so far. These blades can process with an acute degree of straightness and dimensional accuracy for high-load processing by using the excellent rigidity and cutting ability of the vitrified bond. As a result, VT07/12 realizes quality processing for difficult-to-cut materials such as silicon nitride. Thanks to the enhanced bond line-up, this bond series also realizes processing in various fields, such as edge trimming of silicon wafers.

- Realizes thin blades with a vitrified bond.

- Able to process with a high degree of straightness and dimensional accuracy for high-load processing.

- Realizes high quality processing for hard ceramics and sapphire.

- Realizes high quality edge trimming.

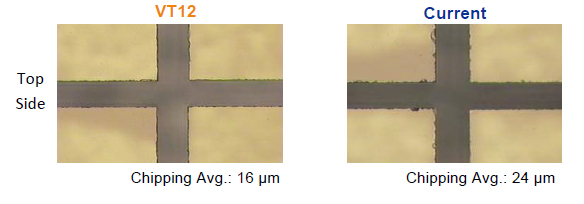

SiC processing

Compared to the existing blade, the VT12 blade can achieve a higher grade of processing for SiC, which has an extremely high hardness.

To use these DISCO blades and wheels (hereafter precision tooling) safely...

Please read carefully and follow the instructions below to prevent any accidents or injuries:

- USE a safety cover (nozzle case, cover), equipped as a standard accessory, to avoid injury.

- DO NOT EXCEED the specified rpm limit indicated on the precision tooling.

- FOLLOW the instruction manual of the equipment to mount the precision tooling properly.

- DO NOT DROP OR HIT the precision tooling. This may cause breakage or injury.

- Always CHECK the precision tooling for chipping or any other damage before starting to use it. DO NOT USE the tooling if there is any damage.

- READ the operation manual of the cutting/grinding equipment before use.

- DO NOT USE the precision tooling with modified or customized equipment.

- DO NOT USE precision tooling that has a different size from the one recommended for your equipment.

- DO NOT USE the precision tooling for any other purpose than grinding, cutting, or polishing.

- Always USE water or coolant to prevent precision tooling damage.