Product Filter

DDS2300

Availability: Product not in stock!

Φ300 mm

SDBG

SDTT

Improves the cut quality of thin wafers with DAF

In separation process for thin wafers with DAF (Die Attach Film), there are issues such as DAF burring forming on the cut surface when full-cut dicing is performed and pickup errors during die bonding. Using the DDS2300 in the dicing process improves DAF cut quality and provides solutions for these issues.

Effective for DAF cutting after the DBG process

When using DAF together with the DBG (Dicing Before Grinding) process, which is suited for thin die manufacturing, it is necessary to attach a DAF to the backside of the separated dies and dice the DAF only. The existing laser process for dicing DAF only sometimes requires consumables such as a surface protective film solution. By using the DDS2300, it is possible to reduce the amount of DAF cut by laser, which reduces cutting debris and contributes to reduced consumable costs.

Realizes stable die separation after Stealth Dicing™ process

The DDS2300 produces stable die separation of wafers which contain a modified layer formed through Stealth Dicing™ process. This process is particularly effective after Stealth Dicing™ process has been applied to thin wafers with DAF.

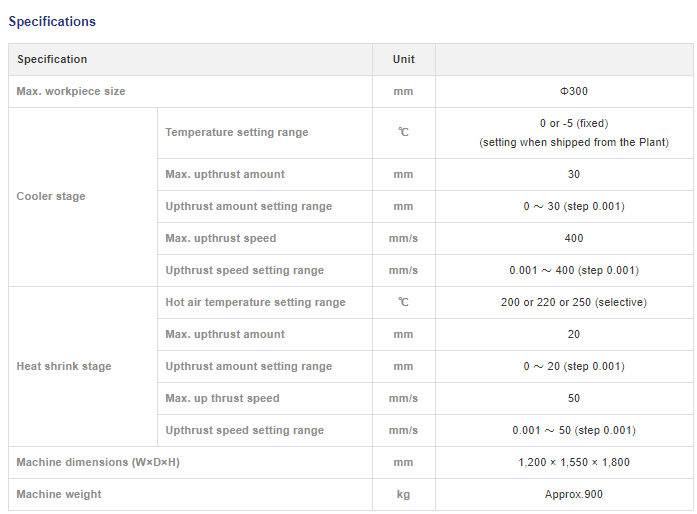

Cool expansion increases DAF separation quality

The cool expansion method is used to achieve stable DAF cleaving. Using the characteristics of DAF where it becomes brittle at low temperatures, expansion is performed in a low temperature environment to realize high precision DAF separation.

Tape frame transport moves the workpiece smoothly to the next process.

The sagging that occurs around the periphery of the dicing tape after expansion can be eliminated through heat shrinking. This enables the workpiece to be transported to the following die bonding process, while it is still mounted on a tape frame and eliminates the need to replace the tape.

Application examples

- DAF separation after blade dicing

- DAF separation after DBG

- Die separation after Stealth Dicing™ process

Work Flow System

- The push-pull arm retrieves the workpiece from the cassette and transfers it to the frame centering stage. →

- The workpiece is aligned on the frame centering stage, then transferred to the intermediate stage. →

-

The workpiece is transferred to the cooler expansion stage, and cool expansion is performed. →

-

The workpiece is transferred to the heater expansion stage, and re-expansion and heat shrinking are performed. →

- The workpiece is transferred to the spinner stage, where it is cleaned and dried. →

- The workpiece is transferred to the UV irradiation stage and UV irradiation is performed. →

- The push-pull arm returns the workpiece to the cassette.

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.