Disco-DAD3361

Availability: Product not in stock!

Φ300 mm

Single spindle

Supports a wide range of applications

DAD3361 is a semi-automatic dicing saw capable of handling Φ300 mm workpieces.* A high-output 1.8 kW spindle is equipped as standard. By selecting a 2.2 kW high-torque, high-rigidity spindle (optional), it is possible to process silicon up to difficult-to-process materials, such as ceramic. Support for blades of up to Φ5 inches is possible with user-specified specifications. In addition, the alignment function for multiple-mounting workpieces to one table frame can be added as an option.

* Supports jig tables with Φ395 mm or smaller circumscribed circles (user-specified specification).

Stable processing quality

By adopting a high-rigidity bridge-type frame and a spindle front-section support structure, which prevents heat shrinkage and vibration, a more stable processing point can be achieved. In addition, a temperature monitoring function that utilizes a spindle temperature sensor has been installed.

Processing Time Reduction

Processing time is decreased up to 2% compared to the existing equipment through axis-speed improvement by adopting servo motors for all axes and optimizing the control parameters.

Improved functions and operation

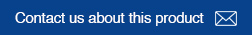

The high-speed, high-accuracy NCS (Non-Contact Setup, optional) reduces blade height measurement time for the processing table by 74%. Further processing quality stabilization is achieved through improved measurement accuracy. In addition, the visibility during kerf check was improved by enabling microscope ring light three-channel switching. This model supports SECS/GEM.

Easy operation

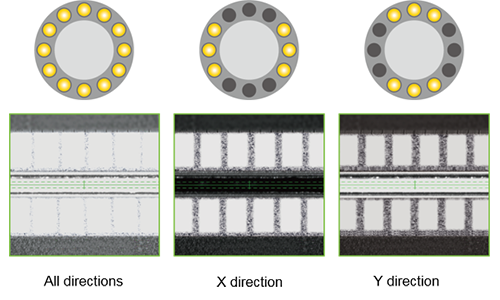

- XIS (Extended Interface System)

Operation buttons consolidated on microscope screens - Wafer mapping

Graphic processing condition display similar to full automation equipment. - Log viewer

Graphic analog data display and equipment data visualization - Help viewer

Displays instructions when error occurs for quick, accurate recovery.

High maintainability

- Enhancement of Dust Prevention Performance on X-, Y-, and Z-axes.

Effective for materials including ceramics where contamination is likely to damage the shaft.

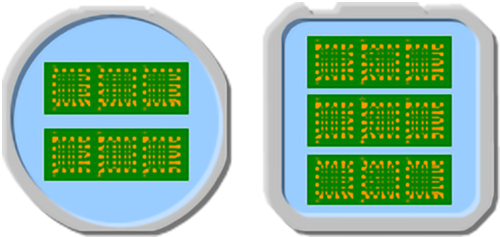

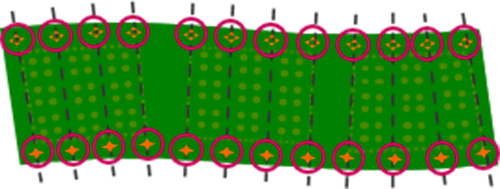

Multi-mounted workpiece processing

Allows multiple package substrates to be attached to one tape frame for processing (Maximum: 16 workpieces).

Measurement alignment

Enables highly accurate processing by performing multiple point alignments for materials with irregular expansion and contraction including resin substrates.

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.