DCS1441

Availability: Product not in stock!

Manual cleaning system with enhanced cleaning performance

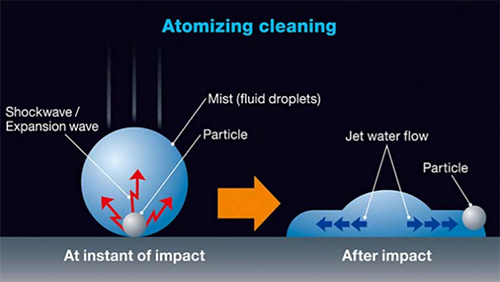

The DCS1441 is the optimal solution for cleaning and drying workpieces processed using a semi-automatic dicing saw or other equipment. High-pressure cleaning with a maximum discharge pressure of 11.8 Mpa and user-created cleaning sequences (settings for the cleaning arm swing speed and spinner rotation speed) offers the optimal cleaning operation for a wide range of workpieces. In addition, the rinse cleaning, atomizing cleaning nozzle, and high-performance atomizing nozzle specifications can be installed as an option. The DCS1441 can greatly reduce the number of processing particles on a wafer.

Supports a diverse range of workpieces

The DCS1441 supports Φ3- to 8-inch tape and frame. The equipment also supports square workpieces up 250 x 250 mm as an option.

Easy operation

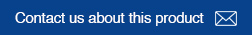

The cleaning sequence can be easily edited using the LCD touch panel. A simplified setting mode, which enables the cleaning operation to start after entering the workpiece size, table rotation speed, and the number of cleaning arm swing or cleaning time, can be selected.

Space saving

The space-saving design has a narrow width.

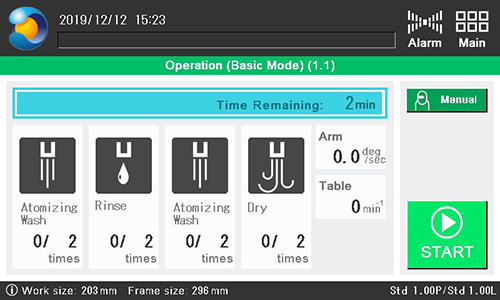

Atomizing cleaning (option)

A unique atomizing cleaning nozzle is used for effective cleaning. Mist generated by the atomization of purified water with high-speed airflow allows processing particles to be removed efficiently. In addition, DCS1441 offers the high-performance atomizing cleaning specification with a higher cleaning effectiveness.

Specifications

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.